The Advantages of Insulated Wall Panels: Why They’re the Ideal Choice for Your Cold Room Construction

Cold rooms are part of many industries where they function to keep products safe and fresh. Every sector related to food and pharmaceuticals is in dire need of cold rooms. Even in the chemical industry, some chemicals need a precise cold temperature that only cold storage provides.

These rooms help in keeping products safe and effective for long periods. A cold room must maintain a stable, low temperature, and proper insulation plays a major role in achieving that. Without good insulation, cold air escapes, energy costs rise, and products risk damage.

Insulated wall panels fulfill all the insulation requirements. These panels offer an effective solution for modern cold room construction. They help maintain internal temperatures and reduce energy use with an improvement in hygiene. We will explain the advantages of insulated wall panels and why they are the best option when building a cold room.

What Are Insulated Wall Panels?

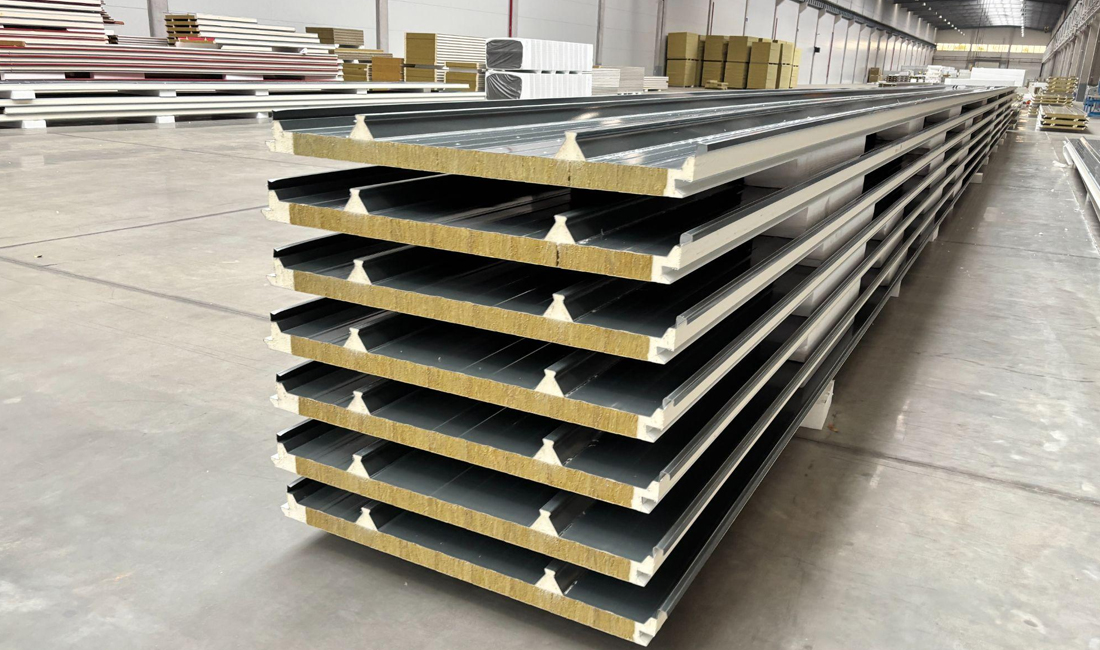

Insulated wall panels provide strong thermal insulation to the inside of the structure. It is a combination of two rigid outer sheets with a high-performance insulating core in the middle. Manufacturers usually use steel or aluminium for the outer sheets and foam-based materials for the core. The core is made of various materials and functions as the most important part. It helps keep heat out and cold in.

Common Core Materials

- Polyurethane Foam with other name as PUF, is one of the best insulators. It provides high thermal resistance with thinner panels.

- Polystyrene (EPS/XPS) is cheaper and still provides good insulation. They are often used in budget cold rooms.

- Polyisocyanurate, with the common name PIR, offers fire resistance in addition to thermal insulation.

Types of Panels Used in Cold Rooms

- Wall panels

- Ceiling panels

- Floor panels

All these panels have a special design that makes them fit tightly to prevent air leakage.

People also call them cold room panels because of their indispensable use in cold storage. Builders use them to create a sealed, energy-efficient space that resists temperature changes.

Why is Proper Insulation in Cold Room Construction Important

Proper insulation is important to achieve as it prevents cold air from escaping and keeps the temperature of the room stable. The cold room functionality may compromise if the insulation is not effective. When builders ignore insulation, it leads to major problems after construction, like the inability of cold rooms to get and maintain the required temperature.

Why Thermal Insulation Matters

- It maintains the internal temperature of the room at a steady level.

- Reduces the strain on refrigeration equipment.

- Protects stored products from getting spoiled.

Effects of Poor Insulation

- Condensation on walls and the ceiling which can lead to mold.

- Spoilage of food or medicine because of unstable temperature.

- High electricity bills because the cooling system works more than needed.

- The cooling system’s shelf life decreases as it wears out faster due to overwork.

Using high-quality insulated wall panels avoids these problems and supports efficient cold room operations. That’s why insulated wall panels are so helpful in cold room construction.

Key Advantages of Insulated Wall Panels

Provide Superior Thermal Insulation

Insulated wall panels are built to hold in cold air. They don’t allow heat from the outside to enter the cold room. This helps maintain a steady, low temperature inside. The inside temperature of the cold rooms stays low irrespective of too much hot temperatures outside.

Example: A dairy cold room that uses insulated wall panels can keep milk and cheese fresh without overworking the cooling system.

Low Energy Use and Cost Savings

Because the panels stop heat from entering, your cold room doesn’t need to use too much energy to stay cold. This brings down electricity consumption and operating costs.

- Less work for the compressor.

- Lower energy bills every month.

- Long-term savings for the business, even if the panels cost a bit more upfront.

Speed Up & Easy Installation

Manufacturers deliver insulated panels pre-fabricated and ready to install. Workers assemble them on-site without the need for separate insulation layers.

- No need for extra insulation work.

- Installation takes less time.

- Labour costs go down.

- Projects finish faster.

This helps businesses set up their cold rooms faster and start using them without long delays.

Hygienic and Easy Maintenance

Insulated wall panels come with a smooth surface. The panels don’t absorb moisture and prevent bacterial and mold growth. The flat surface helps in easy cleaning which benefits the food and medicine storage areas. Cold room operators can clean them easily with water or disinfectants.

- Surfaces stay clean and safe.

- Stops mold from growing.

- Doesn’t allow bacteria to settle.

- Food and medicine storage remains hygienic.

- Meets hygiene standards for food safety.

Example: Daily cleaning of panels is important in a meat cold room. Insulated panels don’t rust or absorb water, so that keeps the space safe.

Structural Durability and Strength

Insulated wall panels are strong and can handle harsh conditions firmly. They can withstand heavy use and regular wear and tear. The panels are able to work for longer periods.

- Don’t bend or crack easily

- Resist rust and corrosion

- Can handle both indoor and outdoor use

- Last many years without frequent repair or replacement

The insulated wall panels have so many durable and strong qualities that don’t require frequent repairing and changing, helping businesses to save money.

Space Saving Design

Insulated wall panels give better insulation even when they are not very thick. They leave more usable room inside the cold storage. This means you get more space inside the cold room.

Example: In a small supermarket cold room, using slim insulated wall panels increases the space available for shelving and product storage.

Environmentally Friendly Construction

Insulated wall panels use recyclable materials and reduce energy waste and pollution from power generation. Their long lifespan also reduces material consumption over time.

- Lower carbon emissions.

- Less material waste during construction.

- Companies meet green building standards more easily.

- Long life = fewer replacements.

So, they are good for your business and the environment.

Why Insulated Wall Panels Are Best for Cold Room Construction

It’s interesting to know that insulated wall panels work better in cold rooms than traditional bricks or concrete.

Best for Low Temperature Environments

Their design makes them better perform in freezing conditions. They don’t crack or leak when exposed to freezing temperatures. They don’t allow moisture to seep in even after years of use. All these features are important for cold rooms.

Fit Without Effort with Cold Room Components

Insulated wall panels connect smoothly with cold room doors, ceilings, and floors. Their tight fit prevents air leaks and maintains internal temperature.

- Fit well with cold room doors.

- Connect smoothly with ceilings and floors.

- No gaps, so no temperature leaks.

- Installation remains clean and efficient.

Customizable Options

Cold rooms are a big need for various industries and requirements vary for each one. These panels come in different sizes and thicknesses with finishes to meet those needs.

- Thicker panels for freezers.

- Thinner ones for chillers.

- Fire-resistant panels if safety is a concern.

- Custom coatings support hygiene, fire resistance, and durability.

You can also pick from different surfaces depending on your industry, like anti-bacterial coatings for medicine storage.

Meet Industry Compliance

Cold rooms need to meet certain rules and standards, especially in industries like food and healthcare. Insulated wall panels help meet those standards.

- Approved for food-grade environments.

- Meet pharma storage guidelines.

- Make it easier to pass safety checks.

Carefully Choose the Right Insulated Wall Panels for Your Cold Room

Insulated wall panels are important for cold rooms, and so their material needs careful selection. After figuring out your cold storage needs, you can find a suitable option for you. Focus on the following features when selecting panels:

Key Factors to Consider

- The R-value shows how well the panel resists heat. The higher value is directly proportional to better insulation.

- Thicker panels give better insulation but take up more space.

- Moisture resistance panels are important for humid areas.

- Some panels offer better fire protection than others. These are best for industries that require panels with fire-retardant properties.

Tips for Choosing Panels

- Check the climate in your area. Hotter areas may need better insulation.

- Pick the panel thickness according to your desired temperature needs

- Know what you’re storing. Medicines may need lower temperatures than vegetables.

- Talk to installers with experience in cold rooms.

- Work with only trusted panel manufacturers

- Don’t go for the cheapest panels. Choose the ones with good quality and long life.

Matching Panels to Cold Room Type

- Use high R-value and thicker panels for freezer rooms

- Medium R-value panels are enough for chiller rooms.

- Panels with hygienic coating and smooth surfaces are best for processing rooms

Why SQPANEL® Panels Are Best Insulated Wall Panels for Cold Room Construction

When it comes to building cold rooms, insulation is everything. SQPANEL® offers two high-quality insulated wall panels—PIR and Rock Wool. Both are strong, long-lasting, and perfect for keeping your cold room energy efficient. PIR (Polyisocyanurate) panels, however, stand out for their excellent thermal insulation. They reduce heat transfer better than most materials. This helps maintain low temperatures with less energy use. Rock Wool panels are great for fire resistance and soundproofing, but PIR panels are the top choice for cold storage needs.

Key Benefits of SQPANEL® PIR and Rock Wool Panels:

- Superior insulation: PIR panels offer low thermal conductivity

- Energy saving: Reduces electricity bills in the long run

- Easy installation: Lightweight and easy to handle

- Durability: Strong core materials with long service life

- Custom sizes: Available to match different cold room designs

- Rock Wool option: Ideal where fire safety is the top concern

Conclusion

Insulated wall panels provide an excellent solution for modern cold room construction temperature requirements. They maintain consistent required temperatures, which reduces energy use and simplifies maintenance. Their strength and easy installation with space-saving design make them a smart investment for businesses in food storage, pharmaceuticals, and beyond. The endless benefits make it clear why these panels are the preferred choice for cold storage solutions.

Want to Know More About Our Products?

View All Products Now