Cold Storage Construction Panels vs Traditional Cold Room Materials: Why Choose Modern Insulation Materials?

Cold storage construction is not just about building a room and placing a cooling unit inside. It is a technical process that needs the right design, structure, and most importantly, the right materials. What you use to insulate and build the room will affect everything, from temperature control to your electricity bill.

For years, traditional materials like brick, cement, and fiberglass dominated cold storage buildings. But now, new options such as insulated metal panels and sandwich panels are changing how cold rooms are built. We are going to compare both options and explain why many companies are moving toward modern insulation materials.

What Is Cold Storage Construction?

Cold storage construction involves designing and building rooms that maintain the low temperature. The types of rooms are necessary for storing various products in many industries, from food processing to pharmaceuticals and chemical storage.

The goal is simple: keep the temperature stable and low so the goods inside remain fresh. But achieving this is not easy. Key considerations include:

- You need to control internal temperature by maintaining a consistent one regardless of external conditions.

- You need to control air leaks and prevent heat transfer to reduce energy consumption.

- Keep checking that the building can withstand temperature fluctuations and moisture. It must prevent outside heat from getting in.

Effective insulation is vital, which results in a low workload on the cooling system. Poor insulation causes a huge increase in energy bills, with potential spoilage of goods.

Traditional Cold Room Materials

What Are Traditional Materials

The cold room is not a new term but an old one, which uses different construction materials. Historically, cold rooms were constructed using materials like:

- Use concrete and bricks in the construction of the outer structure, walls, and floors.

- Use Mineral Wool and fiberglass material for placing inside the walls for insulation.

- Aluminum Sheets or Wood Panels are common for internal linings and structural support in cold rooms.

This setup worked for a long time. Builders knew how to work with these materials. They were easily available and cheap. But over time, issues began to show.

Limitations of Traditional Materials

While these materials have been used for decades in traditional cold room construction, they come with challenges:

Energy Loss Because of Thermal Inefficiency

The main one big problem is energy loss as old material has low insulation properties. Cement and bricks absorb too much heat. The cooling system works harder to keep the internal temperature low as compensation for the heat absorption. That leads to higher energy bills.

Moisture problem

Another issue is moisture. Cold rooms naturally have condensation problems. Fiberglass, traditional insulation material, can absorb moisture. The material also loses its insulating power once it gets wet. This slow losing of insulation power promotes mold growth and structural damage. Repairing this damage is expensive and time-consuming.

Construction

The construction of cold rooms with older materials is not an easy task. It takes many days and weeks, and the builders have to employ big labor for construction. The process also involves many steps, which makes getting the insulation right tricky. If even a small section is left with poor insulation, the cold room becomes inefficient.

Maintenance

It is an important requirement in both old and new cold rooms. The old material has more chances to degrade over time, which requires frequent repairs.

Modern Insulation Materials: Types and Advantages

Modern cold storage uses advanced insulation materials specifically designed for efficiency and durability.

Insulated Metal Panels

IMPs are metal sheets of typically polyurethane or polyisocyanurate that contain an insulating core. The benefits of these sheets include:

- These sheets provide excellent insulation or thermal resistance that reduces energy costs.

- IMP provides quick construction and installation.

- They are highly durable due to their resistance to moisture and corrosion. They also offer safety from physical damage.

- Insulated meta panels have an airtight seal that minimizes air leakage and maintains consistent temperatures.

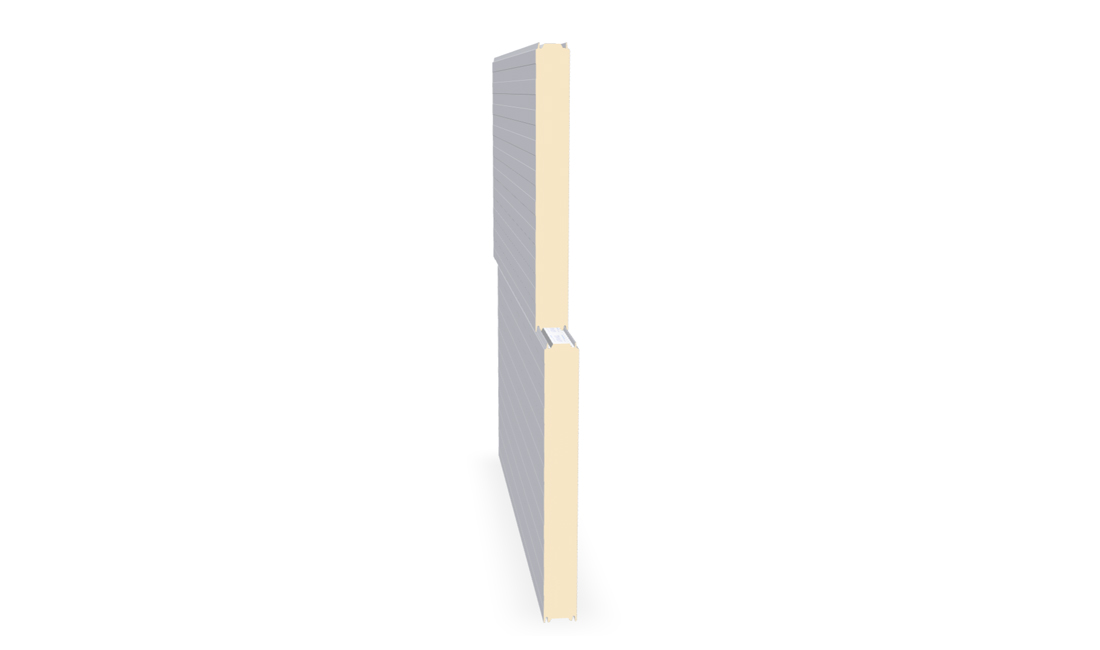

Sandwich Panels

Sandwich panels have an insulating core between two outer layers, just like IMPs. Its advantages are:

- Superior insulation properties make these panels energy efficient.

- Sandwich panels have lower material and installation costs compared to traditional methods. So, these panels are budget-friendly, also.

- These panels are available in various sizes and thicknesses to suit different needs.

Advanced Materials

Innovation in insulation has introduced some advanced materials, which are as follows:

- Aerogel material is lightweight with exceptional thermal properties.

- Composite material combines different substances for enhanced insulation and strength.

These advanced materials improve energy efficiency and are suitable for sustainable building practices.

Most Common and Modern Cold Storage Construction Panels

What Are They?

Pre-fabricated panels are the basic component of modern cold storage construction. These are made up of large walls and ceiling pieces containing metal skins and an insulation core. The most commonly known core is PIR (polyisocyanurate) foam. Other options include PUR (polyurethane) or even more advanced materials like composite foams.

These panels are ready in factories and are ready to install after shipping. They connect together tightly, and there is no gap for air to escape.

Why Are They Better?

Builders prefer these panels because of their thermal performance. PIR panels have high R-values that make them stop heat from moving through them. This feature helps to keep the inside cold and hence consumes less energy. These panels perform far better than older panels.

Its speed of installation is also incredible. These panels come pre-cut, and the workers can assemble them much faster. There is no need to wait for weeks to complete the project. The project can be done in a few days with modern panels.

The outer layer of these panels saves them from moisture as it doesn’t soak up water. These panels lock tightly and which lessens the chance of condensation forming inside.

Modern cold room panels are cleaner and more professional as compared to traditional room panels. You can choose finishes of your choice that are easy to wash. It is especially helpful in the food and medical industries where hygiene is very important.

Why Choose Modern Insulation Materials for Cold Storage Construction?

Energy Efficiency

These panels are energy-efficient because modern insulation material reduces heat transfer. It leads to lower energy consumption and operational costs.

Regulatory Compliance

Advanced materials often meet or exceed building codes and standards for energy efficiency and safety.

Sustainability

Modern insulation panels are sustainable. It reduces carbon footprints and aligns with green building practices.

Design Flexibility

You have great design flexibility with various sizes, thicknesses, and finishes available. These modern panels can be customized to specific project requirements.

All these modern features don’t mean traditional methods are completely useless. They are still usable in small projects or rural areas, and for old materials. But modern panels are a smarter choice for a long-lasting cold room.

Cold Storage Construction Panels vs Traditional Cold Room Materials

We have discussed both panels and traditional cold room materials; here is their comprehensive comparison for more understanding.

Thermal Performance

Traditional materials like bricks and fiberglass do offer some insulation, but not enough for long-term cold storage. They also allow thermal bridging, where heat sneaks through the structure. That makes your cooling units run longer and harder.

Insulated panels have uniform insulation with no gaps. PIR cores give excellent R-values, even with thinner walls. This means you can save space while still keeping the room cold.

Result: Modern panels clearly win here.

Moisture and Hygiene

Moisture is a major enemy in any cold room. Traditional materials have big trapping holes that capture water and cause mold growth. This situation results in bad smells and health problems. Cleaning them is hard and often needs professionals.

Cold storage panels have smooth but coated surfaces, which don’t absorb moisture and are easy to clean. This is especially important in food and medicine storage, where safety rules are strict.

Result: Modern panels offer better hygiene and moisture control.

Build Time

A traditional cold room is labor-intensive work and takes a long time to build. Each layer—from structure to insulation to lining—requires separate steps. Any mistake in one layer can reduce the efficiency of the whole system.

Insulated Prefabricated panels are quicker to build and install. One team can build walls and ceilings at the same time, without needing to wait for cement to dry or insulation to be stuffed into walls.

Result: Panels are much faster to build with.

Durability and Repairs

Traditional materials break down with time. Bricks crack, fiberglass shifts or sags, and wooden linings rot. Repairs are not only costly but also difficult to carry out without shutting down the cold room.

Panels are durable, especially PIR foam doesn’t settle or degrade easily. They offer high resistance against moisture and corrosion and demand less maintenance. If a panel gets damaged, you can replace just that section without disturbing the rest of the room.

Result: Panels offer better durability and easier repair.

Cost with Long-Term Savings

Traditional materials may seem cheaper at first. But their poor insulation means your power bills will be higher. You may also spend more on repairs and cleaning. This costs a lot of money while being in operation in the long run.

Panels cost more upfront, but you need to spend less over time. You use less energy, get fewer breakdowns, and can enjoy a more reliable cold room.

Result: Panels are more cost-effective in the long run.

Why SQPANEL® Panels Are The Best Cold Storage Construction Panels

SQPANEL® PIR panels are a smart choice for cold storage construction. These panels are strong and energy-saving with built to last. They provide excellent insulation due to high-quality Polyisocyanurate foam between metal sheets. It keeps the temperature consistent and reduces electricity use. Whether it’s a small cold room or a large warehouse, SQPANEL® PIR panels deliver top performance in all conditions.

Key Benefits of SQPANEL® PIR Panels:

- High thermal insulation for better temperature control

- Fire-resistant core adds extra safety

- Light in weight but strong in structure

- Quick and easy to install

- Long-lasting with low maintenance needed

Conclusion

Cold storage construction has changed a lot in recent years. Builders no longer rely only on bricks and fiberglass. With insulated panels—especially those with PIR cores—facilities can run more efficiently and with fewer problems.

If you’re planning a cold room, look at the full picture. Don’t just think about the cost of materials. Think about energy use, hygiene, and how long your system will last. Modern insulation materials are a smart choice for most projects.

Want to Know More About Our Products?

View All Products Now