Material Breakdown of Insulated Wall Panels: Pros and Cons of Polyisocyanurate, Rock Wool, and Other Materials

Insulated wall panels play the most important function in the construction industry. Manufacturers prefer insulated material because of their thermal insulation with fire resistance ability and soundproofing feature.

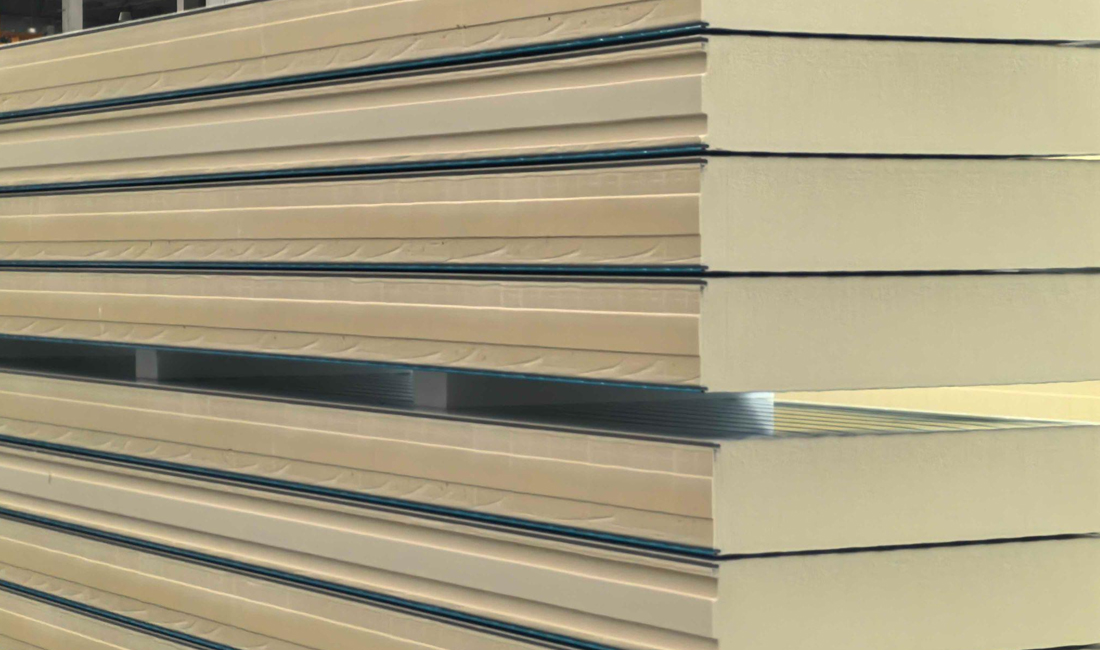

They are basically two metal sheets with core insulation material sandwiched between them. The choice of core material affects the panel’s performance, cost, and suitability for specific applications.

We’ll discuss here the properties of common insulation materials used in wall panels, with their pros and cons. These include Polyisocyanurate or PIR foam, Rock Wool, Glass Wool, and others. It helps you make an informed decision for your project.

Insulated Wall Panels

Insulated wall panels offer structural support and insulation to all buildings. As a prefabricated building component, they are easy to move and install in the required areas. The material is of high quality and suitable for exterior and interior walls.

The benefits it offers make it an ideal material for commercial and residential buildings. The thermal insulation with a durable nature of withstanding harsh conditions allows its use in the industrial sector also.

The core insulation material helps determine the panel’s thermal conductivity, fire resistance, acoustic performance, and overall durability.

Comparing Core Insulation Materials: Properties, Pros & Cons

Polyisocyanurate Foam

Polyisocyanurate is also available on the market under the PIR foam name. It is a type of rigid foam insulation with the main feature of high thermal resistance. These wall panels are ideal because of their insulating properties and lightweight nature.

Properties:

- Approximately 0.022 W/m·K thermal conductivity

- Its density is around 30–40 kg/m³

- It contains fire retardants; however, performance varies under real fire conditions

- High moisture resistance

- PIR is long-lasting with proper installation.

| Pros | Cons |

| High thermal efficiency | Reduced performance at extreme temperatures |

| Moisture resistance | Environmental concerns during production |

| Lightweight and easy to install | May emit toxic gases when burned |

| Space-saving due to high insulation |

Rock Wool or Mineral Wool

Rock wool is another common name for Mineral wool. The basic composition includes natural stone and recycled materials. The material has fire-resistant properties like others, but beats others with its soundproofing qualities.

Properties:

- You will get approximately 0.035–0.045 W/m·K thermal conductivity

- Around 100–150 kg/m³ density

- It is non-combustible and withstands temperatures up to 1000°C

- Hydrophobic and resists water absorption

- It provides excellent sound absorption

| Pros | Cons |

| Superior fire resistance | Heavier weight, challenging to handle |

| Excellent sound insulation | Higher cost compared to other materials |

| Durable and resistant to moisture | Fibers can cause skin irritation during installation |

| Eco-friendly & recyclable |

Glass Wool

The basic composition of glass wool is from recycled glass and sand spun into fibres. It is commonly known for its thermal and acoustic insulation properties.

Properties:

- Approximately 0.030–0.040 W/m·K thermal conductivity

- Around 10–50 kg/m³ density

- Non-combustible

- Not moisture resistance. Poor; absorbs water easily

- Good sound absorption

| Pros | Cons |

| Cost-effective | Loses insulating properties when wet |

| Lightweight and easy to install | Fibers can cause skin and respiratory irritation |

| Good fire resistance | May compress over time, reducing effectiveness |

| Recyclable and made from recycled glass |

Other Common Materials

Expanded Polystyrene

EPS is an affordable and lightweight insulation material. Its best use is in low-cost building projects. You will get moderate thermal insulation, but it comes with low fire resistance. EPS is easy to cut and install, but slowly degrades when exposed to moisture over time.

Extruded Polystyrene or XPS

You will have better moisture resistance and compressive strength with Extruded Polystyrene as compared to ESP. These features make it ideal for exposed damp conditions. XPS is more durable under pressure but still has limited fire resistance.

Phenolic Foam:

Phenolic Foam should be your first choice if you are looking for excellent fire resistance and a very low smoke production material. This feature makes it a safer option for a fire-sensitive environment.

You will get high thermal efficiency, but it tends to be brittle, making its installation trickier. Phenolic Foam is not suitable as a budget-friendly option because it is one of the most expensive insulation choices.

Comparative Analysis Table

| Property | PIR Foam | Rock Wool | Glass Wool | EPS/XPS |

| Thermal Conductivity | ~0.022 W/m·K | ~0.035–0.045 W/m·K | ~0.030–0.040 W/m·K | ~0.030–0.040 W/m·K |

| Fire Resistance | Moderate | Excellent | Excellent | Poor |

| Moisture Resistance | High | High | Low | Moderate |

| Acoustic Performance | Moderate | Excellent | Good | Poor |

| Density | Low (~30–40 kg/m³) | High (~100–150 kg/m³) | Low (~10–50 kg/m³) | Low (~10–50 kg/m³) |

| Cost | Moderate to High | High | Low | Low |

| Environmental Impact | Moderate | Low | Moderate | High |

Pick Best Material for Your Next Construction

The selection of appropriate insulation material depends upon various factors. These factors include building requirements, budget, climate, and specific performance needs.

- Rock wool is a perfect material for getting fire-resistant properties. Its noncombustible nature and ability to withstand high temperatures make it a preferred option for various constructions.

- PIR foam panels have superior thermal insulation. This feature makes it suitable for energy-conscious design.

- Glass wool is a budget-friendly option among other solutions with the best thermal and acoustic properties.

- Rock wool and PIR are both moisture-resistant materials. They reduce the risk of mold and degradation, and are perfect for moisture-prone areas.

Some points need your attention before deciding on your insulated wall panels,

- Building Codes: Make sure materials compliance with local fire and insulation regulations.

- Installation Environment: Areas have exposure to moisture, temperature extremes, and noise levels.

- Performance: Check the durability and maintenance requirements of the material.

- Environmental Impact: Peek into the sustainability and recyclability of the insulation.

Why SQPANEL® Panels’ Are Best Insulated Wall Panels

SQPANELS makes strong and reliable insulated wall panels that work well for many building types. They offer two main types — PIR panels and Rock Wool panels. Most customers choose PIR panels because they deliver better thermal insulation and help reduce energy costs.

Installers find them easy to handle because they are lightweight and quick to install. Rock Wool panels are a good choice for projects that need high fire protection and soundproofing. While both panels offer great durability, PIR panels remain the top pick for most projects due to their performance, efficiency, and overall value.

Key Benefits of SQPANEL® PIR and Rock Wool Panels:

- PIR panels keep buildings warmer for longer

- Easy to carry and install on-site

- Help save on heating and cooling bills

- PIR panels offer high thermal insulation

- Lightweight

- long lifespan

- Rock Wool panels provide fire resistance

- Rock Wool is great for sound insulation

- Both types are durable and weather resistant

- Suitable for commercial, industrial, and residential buildings

Conclusion

Insulated wall panels hold an important place in modern construction. With its energy efficiency and safety features, it offers convenience during installation. Availability of various types based on material, users’ requires a careful material breakdown of various insulated wall panels with their properties, advantages, and limitations. Knowing all details helps us to make informed decisions according to specific project needs.

PIR Foam is known for its high thermal performance and moisture resistance. This feature makes it ideal for energy-efficiency design. Rock wool panels excel in fire resistance and sound insulation. It is suitable for buildings with proper safety requirements.

Glass wool is an economical option with reasonable performance. The panels need careful handling and protection from moisture. You can select the most suitable insulation material that meets your building demands by carefully evaluating the characteristics of each material.

Want to Know More About Our Products?

View All Products Now